TERAOKA’s Technology

Manufacturing that brings together the diverse technological strengths of TERAOKA

NOLOGY

Teraoka Seisakusho combines the technical capabilities which it has built up over 100 years with a spirit of challenge to take on new challenges one after another to create and provide new value to its customers.

TERAOKA's Research and Development

TECHNOLOGY 01

Development

What are “TERAOKA’s strengths”?

“TERAOKA’s strengths” are the tape design and manufacturing technologies that have been cultivated over 100 years as a tape manufacturer. Design technology is, so-called, the technology of "designing" tapes by adjusting materials such as adhesives and base materials to achieve the required characteristics. Manufacturing technology is the technology to stably produce the "designed" tapes in a high quality and stable manner. By actively promoting collaboration with customers, other companies and external organizations, and by demonstrating these "TERAOKA’s strengths", we create attractive and high value-added products.

Manufacturing that combines the diverse technological strengths of Teraoka Seisakusho

By making the most of “TERAOKA’s technological strengths”, we develop new products and provide technical support tailored to our customers. Furthermore, TERAOKA's efforts are not limited to the field of tapes. By applying the “TERAOKA’s strengths”, we will create unprecedented, groundbreaking products that meet the demands of ever-changing markets and customers, and will also challenge ourselves in of entering new business fields.

Strengths of Teraoka Seisakusho

Design and Manufacturing Technology

- Design Technology

- Manufacturing Technology

Quick response and convincing explanation

Challenges to New business

One of the new businesses is ACULAH®. Until now, in order to bond different materials such as metal and rubber, vulcanizing adhesives containing large amounts of organic solvents were applied to the surface of the material by brush or spray, but when applying by brush or spray, a large amount of organic solvent evaporates, which creates a poor working environment and makes it difficult to apply evenly. To solve these problems, we developed ACULAH®, a vulcanizing adhesive in sheet form that is easy and safe for anyone to use.

TERAOKA’s Technology

TECHNOLOGY 02

TERAOKA's technological capabilities have produced a wide range of products to meet the demands of the times

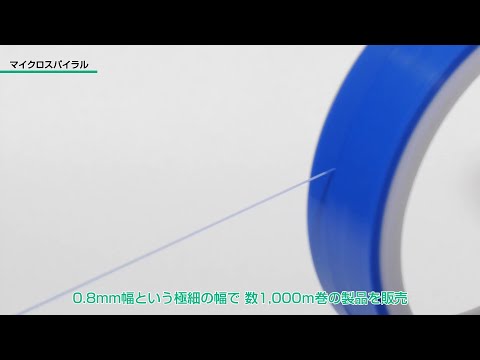

Adhesive tapes are required more than just adhesive strength. For example, in the field of electronic devices, in addition to the need for thinner and narrower tapes to match the increasingly miniaturized electronic devices, the properties such as heat resistance, electrical insulation and removability are required. In the battery field, tapes with a wide variety of functions are required to suit the application, such as chemical resistance that does not affect the electrolyte. TERAOKA's technological capabilities which it has developed over the past 100 years and its flexible creativity to incorporate cutting-edge technology at any time enable it to respond to these various characteristics and to apply and develop not only adhesive tapes but also products other than tapes.

Environmentally Friendly Manufacturing

TERAOKA is also actively involved in environmental conservation initiatives. We work on environmentally friendly products throughout our supply chain and reducing the amount of organic solvents used in the manufacturing processes.

Tape Manufacturing Flow

Design Technology

Adhesive / Adhesive Design Technology / Base Material Selection Technology

By combining and adjusting various materials based on TERAOKA's unique adhesives, it is possible to design adhesive tapes with a wide variety of functions.

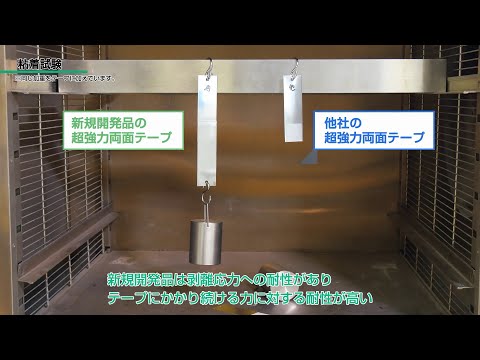

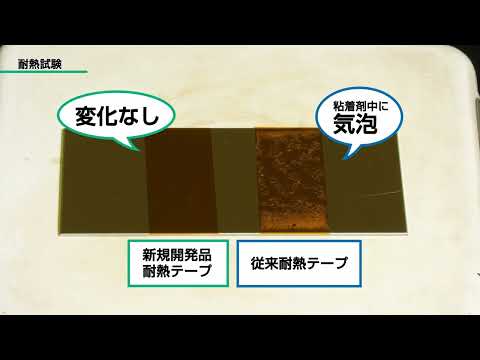

High temperature resistance Super-strong double-coated adhesive tape!

Enough to lift a car!

Enough to withstand high temperatures!

No adhesive left You can remove cleanly!

Manufacturing Technology

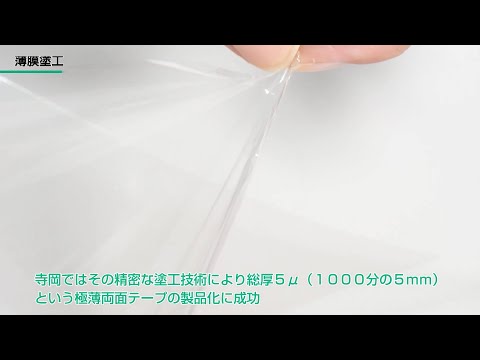

Wide variety of coating methods! Thin! Dots!

Amazing Thinness!

Environmental Conservation

For the sake of the next generation of mankind and the planet, we are also actively involved in environmental conservation. We have biomass products that use renewable biological materials, and products that can be recycled together with cardboard, allowing you to leave the tape on when disposing of cardboard as recyclable waste. We are also working to introduce new systems that significantly reduce emissions of organic solvents that cause air pollution and CO2, which contributes to global warming, and to establish coating technologies that do not use organic solvents in the first place.

-

Solvent Reduction

-

Biomass

-

Recycling

TERAOKA's Technological Development

TECHNOLOGY 03

Expansion

TERAOKA’s technology into Products and New value

Adhesive tapes developed with TERAOKA's diverse technological capabilities are applied in a variety of fields. They cover a diverse range of business areas, including “Electronic components”, “Smartphones and Mobile devices”, “mobility and New energy”, “Living and Packaging”, “Infrastructure and Construction” and “Environment”. From now on and forever, TERAOKA will continue to deliver new value to the market, armed with its technological capabilities and its ability to boldly take on new challenges.

Product range expanding based on TERAOKA's technology

Thank you for reading to the end.

In addition to the technologies introduced here, we have many other technologies.

If you have any requests for other tapes or have any other problems, please feel free to contact us using our

inquiry form.

We look forward to hearing from you.

For more information about our products, please contact the nearest branch or sales office.